Emerging Robotics Technologies and Their Business Applications

The landscape of business automation is rapidly transforming, significantly driven by robotics technologies. Companies are increasingly adopting robots not only to enhance operational efficiency but also to reduce costs and improve product quality. Innovations in robotics allow for increased precision in manufacturing processes. Autonomous robots equipped with advanced sensors and AI capabilities can perform complex tasks that were traditionally completed by human workers. Moreover, these robots work tirelessly and have the ability to constantly learn and adapt through machine learning algorithms. This leads to improved productivity across various sectors, including manufacturing, logistics, and healthcare. Industries benefit from robotic applications in various fields, leading to enhanced safety and reduced human error. To stay competitive, businesses need to integrate these solutions into their operations effectively. The deployment of robotics aids organizations in achieving quicker turnaround times and better scalability. Furthermore, real-time data analysis from robotic systems contributes to informed decision-making processes and resource optimization. In summary, the integration of emerging robotics technologies is not optional; it is imperative for modern businesses wanting to thrive in a competitive landscape.

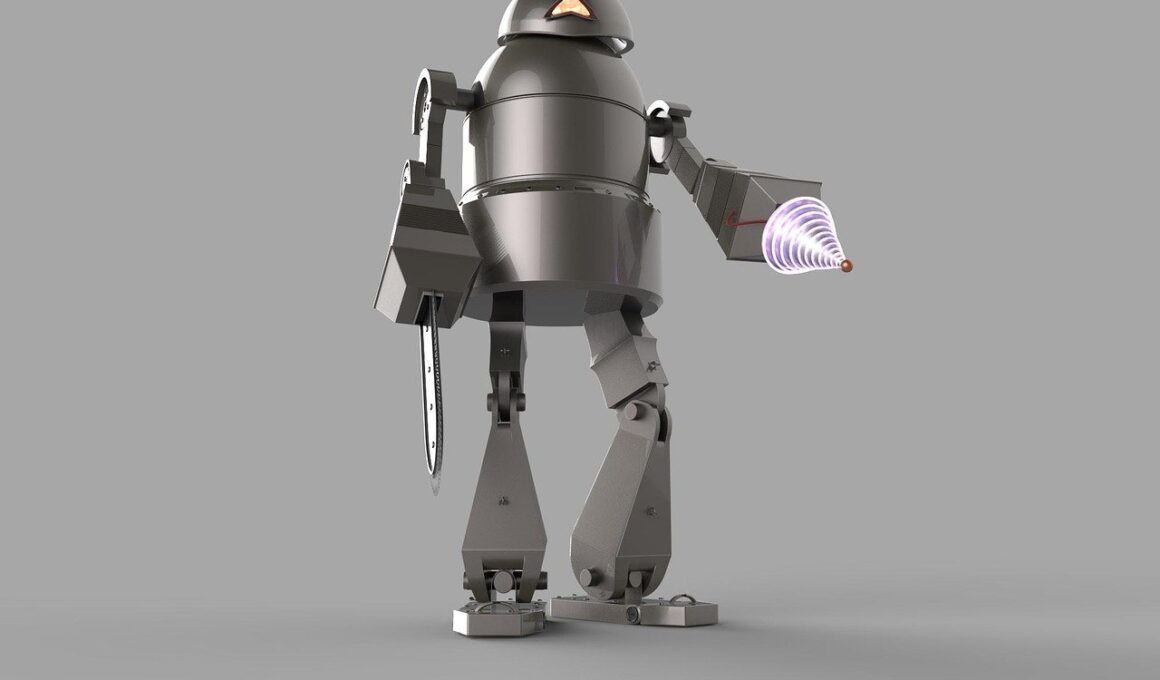

Types of Robotics Technology

Three main types of robotics technologies are garnering considerable attention in business: industrial robotics, collaborative robots, and service robots. Industrial robots excel in repetitive tasks, often found in assembly lines, where they perform tasks such as welding, painting, and packaging. These robots are designed for high reliability and accuracy, enabling businesses to maximize productivity. Collaborative robots, or cobots, work alongside humans, assisting with tasks that require both human judgment and machine efficiency. Their design focuses on safety and ease of use, making them ideal for smaller enterprises not looking to replace human labor entirely. Service robots, on the other hand, are employed in healthcare, hospitality, and retail settings to enhance the customer experience. They can perform a range of functions, from delivering items in a hospital to providing information in a store. As the robotics industry continues to evolve, businesses have the opportunity to leverage these diverse technologies to meet specific needs. Understanding these types helps executives make informed decisions on which robotic solutions to deploy for maximum effect.

The current advancement of robotics is heavily influenced by artificial intelligence integration. AI has allowed robots to process data and learn from experiences, improving their performance significantly over time. Modern robotics now includes sophisticated algorithms that enable machines to recognize objects and navigate their surroundings efficiently. For instance, AI-powered robots can identify best paths for logistics operations, reducing transit times and costs. Additionally, this technology enhances robotic vision systems, making them capable of quality inspections in manufacturing. The ability to analyze images and detect defects ensures only high-quality products reach consumers, leading to greater brand reputation. Moreover, companies can utilize AI to forecast demand patterns utilizing robotic assistants, accessing market analytics that informs strategic decisions. Robotics powered by AI can also contribute to predictive maintenance protocols, identifying issues before they escalate into expensive breakdowns. This proactive approach minimizes downtime and ensures continuous operations. Ultimately, AI integration transforms how businesses leverage robotics, ushering in a new era of efficiency and adaptability across multiple sectors. Companies investing in these technologies stand to gain a competitive edge over others in the market.

Impact on Labor Market

The rise of automation and robotics has sparked discussions regarding its impact on the labor market. As businesses increasingly adopt robotics technologies, there is growing concern that jobs may be at risk. However, it’s essential to consider that while some roles may become obsolete, new opportunities arise within this evolving landscape. Automation can relieve employees from mundane and repetitive tasks, allowing them to focus on more creative and strategic aspects of their roles. For instance, in manufacturing settings, robots can handle assembly line work, while human workers can concentrate on quality control and decision-making processes. Moreover, as robots take on tasks requiring precision, workers may transition into developing, maintaining, or programming robotic systems, necessitating a skilled workforce. Training programs focusing on upskilling workers become vital to ensure that the labor force adapts to technological changes. Although the dynamics of labor markets will shift, embracing robotics can yield a more skilled workforce, ultimately leading to increased innovation and job creation in sectors that may not yet exist today. The narrative surrounding job loss needs to be balanced with the potential for job evolution.

As industries continue to implement robotics technologies, cost perceptions in adoption have shifted dramatically. Initially, small and medium enterprises hesitated to invest in robotics due to capital expenditures and maintenance costs. However, the declining price of robotic systems and components has incentivized businesses to reconsider. The availability of various funding options, including grants and loans dedicated to technology adoption, offers additional support. Moreover, the long-term benefits achieved through increased efficiency and productivity quickly offset initial investments. This financial rationale has prompted numerous companies to view robotics not merely as a luxury but an essential strategic asset. With advancements in technology, small businesses now have access to user-friendly robotic solutions capable of addressing specific needs at affordable rates. Furthermore, technological advancements allow for faster implementation, reducing operational disruptions during transitions. Partners offering support services and integration expertise simplify robotic deployment, making it approachable for those with limited technological proficiency. As a result, these factors lead to a growing perception that investing in robotics is no longer a daunting endeavor but rather a necessary step towards maintaining competitiveness. This has broadened the accessibility of robotic technologies across various industries.

Real-World Applications

Numerous industries are currently witnessing the profound impacts of robotics technologies, showcasing successful real-world applications across a spectrum of sectors. In manufacturing, for example, automotive giants employ robotic arms for welding and assembly processes. Such applications have resulted in increased throughput and precision, translating to fewer defects and higher customer satisfaction. In the retail sector, robots handle inventory management by tracking stock levels and replenishing shelves, streamlining operations while freeing employees for customer-facing roles. Additionally, the healthcare industry benefits from service robots assisting during surgeries, elevating operational precision while minimizing risk. By utilizing robotic assistance, healthcare providers enhance patient care and clinical outcomes, creating a safer environment. In agriculture, robotic solutions are rapidly becoming essential for tasks such as planting, harvesting, and monitoring crops. Automated systems enable farmers to operate more efficiently, maximizing yields and ensuring food security. The logistics domain also extensively incorporates robotics, with autonomous vehicles optimizing delivery routes. From manufacturing to agriculture, the versatility of robotics technology showcases a transformational potential. By implementing clever automation strategies, these industries are effectively increasing their service capabilities while meeting growing consumer demands.

As we look to the future, the role of robotics in business innovation is poised to become even more integral. Continuous advancements in robot designs and functionalities promise further transformations across various industries. Future technologies might enable robots to engage in more complex tasks, including emotional recognition and multi-modal interactions with humans. Such capabilities could reshape customer service experiences, transforming the way consumers perceive and engage with brands. Moreover, the integration of VR and AR technologies with robotics can offer immersive training experiences for employees or unique marketing strategies for brands. Furthermore, as cities evolve into smart ecosystems, robotics technologies will play crucial roles in urban management and public safety. Emerging concepts include drones for delivery services and automated policing drones, enhancing community safety. As businesses continue to innovate, considering ethical implications surrounding robotics development will be vital. Ensuring responsible growth requires collaboration between technology developers, policymakers, and business leaders to help navigate the complexities of integrating robotics into society. Overall, the next phase of robotic evolution holds immense potential to reshape our lives, driving unprecedented improvements in quality of service and operational excellence.

Embracing robotics technologies encourages collaboration across industries. As organizations realize the benefits, partnerships between tech companies and traditional sectors will flourish. Working together, industries can develop unique solutions that address specific challenges faced. This collaborative spirit fosters innovation leading to the creation of more sophisticated robotic systems. For example, healthcare specialists can partner with robotic engineers to create devices tailored for patient care. Businesses recognizing the importance of collaboration will solidify their market positions while enhancing the quality of service. When companies share knowledge and expertise, they cultivate a culture of learning that drives sustainable growth. This approach enables various sectors to embrace change easily, adapting to future demands. Thus, fostering collaboration within and across industries becomes essential to achieving success as robotics technologies evolve. The positive impacts are vast, from improving product quality to streamlining operations. As more organizations recognize these dynamics, we can expect a surge in robotics development and adoption over the coming years. These partnerships will shape the future of industries, driving business innovation, transforming service delivery, and enriching the customer experience.