The Importance of Supply Chain Agility in Cost Reduction

In today’s competitive business landscape, supply chain agility has emerged as a critical factor for managing costs effectively. Companies must respond rapidly to changing market dynamics, ensuring they can adapt their supply chains to optimize expenses. Agility enables organizations to react swiftly to fluctuations in demand, thereby minimizing excess inventory and reducing warehousing costs. Furthermore, it allows businesses to leverage real-time data for making informed decisions about their supply chain operations. This adaptability not only supports cost reduction but also enhances service levels. A responsive supply chain can lead to improved customer satisfaction, reinforcing brand loyalty. By streamlining processes and incorporating technology, companies can achieve a balance between efficiency and flexibility. This balance paves the way for cost savings without compromising quality. In essence, cultivating agility within the supply chain leads to more strategic and financially viable operations. Organizations focusing on flexibility tend to foster innovation, which can uncover additional cost-saving opportunities. Therefore, businesses that prioritize supply chain agility are better positioned to thrive in a dynamic economic environment.

Cost management strategies are more effective when they are grounded in robust data analytics. Implementing advanced analytics allows businesses to identify inefficiencies and bottlenecks within their supply chains. By visualizing data trends, organizations can pinpoint areas where costs arise, laying the groundwork for targeted intervention. For instance, analyzing procurement data enables companies to renegotiate supplier contracts or consolidate purchasing to obtain bulk discounts. Predictive analytics can forecast future demand patterns, facilitating more efficient inventory management. As a result, businesses reduce holding and stockout costs through improved inventory turnover. Additionally, data analytics can influence transportation decisions, optimizing routing and reducing shipping expenses. Organizations leveraging these insights often achieve a sustainable competitive advantage. They can align production schedules with demand forecasts and decrease lead times. Furthermore, measuring key performance indicators (KPIs) helps companies to understand their supply chain’s performance concerning cost efficiency. These metrics serve as valuable benchmarks to guide continuous improvement efforts. Therefore, harnessing data-driven insights enables smarter decision-making processes, significantly enhancing supply chain cost management practices.

Integrating Technology for Cost Efficiency

The integration of technology in supply chain management plays a crucial role in promoting cost reduction. Technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) enable organizations to automate processes and enhance visibility across the supply chain. Automation reduces labor costs, minimizes errors, and speeds up operations, leading to significant savings. For instance, AI algorithms can optimize inventory levels and forecast demand accurately, reducing the risk of overstocking or stockouts. Additionally, IoT devices provide real-time tracking of shipments, allowing companies to manage logistics more efficiently. By identifying delays or disruptions in the supply chain, businesses can promptly address issues and mitigate costs. Moreover, warehouse automation through robotics streamlines operations, reducing overhead expenses associated with manual labor. Also, utilizing cloud-based solutions facilitates better collaboration with suppliers and partners. Improved communication helps in effective negotiation and coordination, further driving down costs. Therefore, embracing technological advancements is vital for organizations aiming to enhance agility and significantly reduce costs within their supply chains.

Another essential element in achieving cost reduction through supply chain agility is fostering strong supplier relationships. Collaborative partnerships enable businesses to work jointly with suppliers to identify areas for joint cost savings. Establishing open lines of communication allows for sharing market intelligence, resources, and best practices, which can lead to improved efficiency. Long-term relationships with reliable suppliers often result in better pricing and terms, as suppliers recognize the value of consistent business. Additionally, suppliers are more likely to prioritize organizations that demonstrate commitment and loyalty. Engaging suppliers in performance improvement initiatives can enhance overall supply chain performance, leading to reduced costs across the board. Organizations that collaborate effectively often find innovative solutions that benefit both parties. Furthermore, creating joint risk management strategies ensures that businesses can navigate challenges together without incurring excessive costs. Empathy and understanding in supplier negotiations can bring about favorable terms and conditions, driving down procurement expenses. By recognizing that suppliers are crucial partners, companies can unlock new cost-saving opportunities and enhance their overall supply chain agility.

Lean Principles in Supply Chain Management

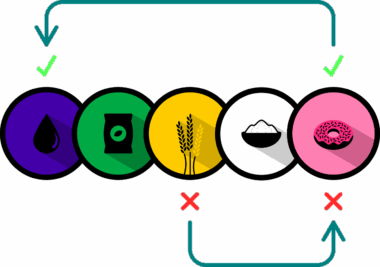

Implementing lean principles within the supply chain framework is another viable strategy for reducing costs. Lean management emphasizes eliminating waste in processes, which directly correlates with lowering operational expenses. By assessing every stage in the supply chain for inefficiencies, organizations can streamline operations and minimize waste. This approach encourages a focus on value-added activities while preserving resources. For instance, organizations can adopt techniques such as Value Stream Mapping (VSM) to analyze workflows and identify non-value-adding steps. After pinpointing these activities, businesses can redesign processes to optimize efficiency. Moreover, training employees in lean methodologies fosters a culture of continuous improvement, motivating teams to seek out new ways to drive cost reductions. Lean supply chains also contribute to faster response times and improved flexibility, crucial for adapting to market changes. Organizations can align production tightly with customer demand, which consequently minimizes holding costs. The adoption of lean principles not only reduces costs but also creates a more agile supply chain that is responsive to customer needs and market fluctuations. Building an efficient supply chain through lean strategies is relevant considering the increasing competition and demand for cost-effective solutions.

Finally, effective management of logistics is a crucial aspect of ensuring supply chain agility and cost reduction. Transportation comprises a substantial portion of supply chain costs, making its optimization vital. To reduce these expenses, organizations can evaluate their transportation networks to identify the most efficient routes and carriers. Employing technologies such as Transportation Management Systems (TMS) can aid in planning shipments, consolidating loads, and comparing carrier rates. By streamlining logistics workflows, companies can minimize delays and reduce freight costs. Additionally, utilizing regional warehouses strategically can diminish shipping distances and expedite delivery. This approach helps companies to meet customer expectations while controlling transportation costs. Collaborating with logistics providers often results in better shipping rates and terms, fostering partnerships that are mutually beneficial. Organizations can also explore alternative transportation methods, such as rail or intermodal shipping, which may present cost advantages over traditional trucking. Overall, proactive logistics engagement, combined with strategic decision-making and technology integration, significantly contributes to establishing an agile and cost-effective supply chain.

In conclusion, the landscape of supply chain cost management is ever-evolving, requiring businesses to adopt agile methodologies for success. By emphasizing agility, companies can not only enhance cost-reduction efforts but also improve overall operational performance. The fusion of technology, data analytics, collaborative supplier relationships, lean principles, and efficient logistics creates a holistic approach to managing supply chain challenges. Organizations that prioritize flexibility in their supply chains can navigate market unpredictabilities more adeptly. Moreover, these capabilities position businesses to seize innovative opportunities for growth and maintain competitive advantages. As companies strive for better cost management, investing in supply chain agility will yield substantial returns, from reduced operational expenses to enhanced customer satisfaction. Every step taken towards agility translates into decrease in costs without compromising quality or service. Hence, the importance of supply chain agility in cost reduction cannot be overstated. A proactive approach that leverages all available resources, including technology and human capital, is essential for long-term sustainability. Therefore, businesses aiming for excellence in supply chain management must embrace agility as a primary strategy for optimizing costs and improving profitability.

To summarize, agility in the supply chain is indispensable for modern businesses aiming to manage costs effectively. Companies that leverage agility can respond faster to market conditions, streamline processes, and drive down expenses sustainably. The combination of advanced technologies, strong supplier interactions, and lean methodologies fosters operational efficiency. Moreover, the ability to analyze data and implement innovative logistics strategies further enhances performance. Firms that embrace agility are not only optimizing their current operations but also positioning themselves to seize future opportunities. Success in supply chain cost management requires a proactive approach to adapt to changing environments. Investing in agility ultimately pays dividends through enhanced profitability and customer satisfaction. Effective management practices and a focus on continuous improvement enable organizations to thrive amid challenges that arise. Thus, the journey towards cost reduction through supply chain agility should be a top priority for all businesses striving for both efficiency and growth. In conclusion, embracing agility is not merely a strategic initiative; it is an essential component of a resilient supply chain capable of adapting swiftly to ever-changing demands in today’s market.