Implementing Lean Practices in Supply Chain Management

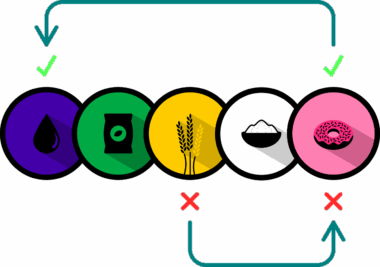

Implementing lean practices in supply chain management is crucial for optimizing operational efficiency. Lean practices focus on eliminating waste, improving process flow, and maximizing value for the customer. Organizations that adopt these techniques can significantly reduce costs, enhance product quality, and foster a culture of continuous improvement. A profound understanding of the principles of lean management is essential for successful implementation. Lean principles such as Value Stream Mapping help organizations identify non-value-added activities, allowing them to streamline operations accordingly. Additionally, engaging employees in identifying and solving problems is fundamental to nurturing a proactive workforce. Techniques such as the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) create a clean and efficient workspace for employees. Furthermore, regular training and development on lean techniques enhance the team’s ability to apply lean practices effectively, yielding long-term benefits. Ultimately, organizations can create a competitive advantage through cost savings, improved process efficiency, and enhanced member satisfaction by embedding lean principles throughout their supply chains.

One of the fundamental aspects of lean supply chain management involves fostering collaboration among stakeholders. This collaboration can significantly enhance communication and lead to a more synchronized supply chain. When suppliers, manufacturers, and distributors work together, they can share critical information, which leads to better decision-making. For example, regular meetings and updates help all stakeholders stay on the same page regarding demand forecasts, production schedules, and inventory levels. By implementing collaborative tools such as cloud-based platforms, organizations can enhance their ability to share data in real-time. This streamlined communication ultimately reduces lead times and improves responsiveness to market changes. Moreover, creating partnerships with suppliers can lead to joint problem-solving and innovation, which are vital for continuous improvement. Companies must focus on building strong relationships by engaging in transparent negotiations and investments in joint development efforts. This collaborative approach allows all parties involved to proactively address issues and respond more effectively to customer demands. The result is a more agile and resilient supply chain capable of adapting to fluctuations in the marketplace efficiently.

Another key element of lean supply chain management is the concept of Just-In-Time (JIT) inventory. This approach enables businesses to minimize inventory costs while ensuring they have the necessary materials on hand to meet customer demands. By reducing excess inventory and associated carrying costs, companies can allocate resources more efficiently. JIT practices rely heavily on accurate forecasting and reliable supplier relationships to maintain consistent product flow. This ensures that materials arrive precisely when needed, minimizing the need for large storage spaces. Implementing JIT practices requires disciplined planning and coordination to ensure timely deliveries from suppliers. As a result, organizations can significantly reduce waste associated with overproduction or excess stock. Furthermore, smaller inventory levels tend to lead to improved product quality since there is less likelihood of obsolescence. Businesses can benefit from real-time inventory tracking technologies to optimize their JIT strategies. This technological integration ensures that supply chains remain streamlined, aligning production with customer needs effectively, thus achieving overall cost reductions within the supply chain.

Continuous Improvement through Kaizen

Continuous improvement is a fundamental philosophy within lean supply chain management, and Kaizen embodies this ideal. Kaizen encourages small, incremental changes that can lead to significant improvements over time. By fostering a culture where all employees can contribute ideas and feedback, organizations can create an environment of innovation. Regularly scheduled meetings dedicated to brainstorming and assessing current processes are essential for generating new ideas. Every team member’s involvement promotes ownership of processes, which encourages an ongoing commitment to optimizing operations. Moreover, implementing Kaizen events can rapidly identify and address specific issues within the supply chain, effectively eliminating inefficiencies. This process of continuous evaluation and adaptation allows businesses to stay competitive in a constantly changing market. Another vital aspect of Kaizen is the importance placed on metrics and data collection. By reviewing performance metrics consistently, organizations can highlight areas needing improvement and track the impact of changes implemented. This data-driven approach ensures that management can make informed decisions regarding resource allocation and process enhancements. Therefore, embracing the Kaizen philosophy is pivotal in achieving long-term success.

Value Stream Mapping (VSM) serves as a powerful tool in identifying waste within the supply chain process. It visually represents the flow of materials and information, allowing organizations to pinpoint areas of inefficiency swiftly. By mapping current processes, companies can identify bottlenecks and delays, which are critical to understanding supply chain dynamics. In executing VSM, teams are encouraged to involve employees across various departments to gain insights into the entire supply chain journey. A proactive approach to identifying and addressing waste often leads to innovative solutions. After mapping, organizations can prioritize improvement initiatives based on their impact on operational efficiency. Empowering employees to suggest improvements fosters a sense of ownership, enhancing team morale. Additionally, organizations can quantify the expected benefits of streamlining processes identified during the mapping exercise. This approach ensures that key stakeholders remain engaged and focused on collective outcomes. Overall, Value Stream Mapping acts as a catalyst for change, ultimately leading to reductions in costs and improvements in customer satisfaction, reinforcing the essential purpose of lean practices.

Leveraging Technology in Lean Practices

The integration of technology is vital for implementing lean practices within supply chain management effectively. Advanced technologies such as automation, data analytics, and artificial intelligence play a significant role in enhancing efficiency. Automation helps eliminate manual processes that can introduce errors and slow down operations. Additionally, data analytics enables organizations to enhance decision-making by providing real-time insights into inventory levels and customer demand. This technology-driven approach leads to smarter inventory management and faster responses to market fluctuations. Artificial intelligence applications can streamline logistics by optimizing delivery routes, thus reducing transportation costs. Integrating these technologies allows organizations to align production with current market needs more efficiently. Furthermore, implementing Internet of Things (IoT) devices can ensure that assets remain connected and monitored throughout the supply chain. By gathering data from connected devices, organizations can respond to issues before they escalate into larger problems. Therefore, leveraging technology is a critical component of successful lean supply chain implementation, ensuring long-term sustainability and competitive advantage in an ever-evolving marketplace.

Finally, measuring the effectiveness of lean practices is essential for continuous improvement within supply chains. Businesses must develop a set of key performance indicators (KPIs) to track the performance of their supply chain initiatives. Metrics such as lead time, inventory turnover rate, and customer satisfaction scores provide insights into efficiency and effectiveness. Regularly reviewing these KPIs allows organizations to assess the impact of implemented lean strategies and make necessary adjustments. Establishing a feedback loop ensures that insights gained from performance metrics are considered when planning future lean initiatives. Moreover, fostering an open environment for communication and feedback encourages employees to share their observations regarding process improvements. Regular training sessions for staff on performance measurement tools can further enhance their capabilities in monitoring progress. This proactive approach helps organizations adapt quickly to new challenges and maintain competitive advantages. By committing to ongoing evaluations and adaptations based on measurable outcomes, businesses can secure a path of continuous improvement and operational excellence, aligning with lean supply chain principles effectively.

In conclusion, implementing lean practices in supply chain management offers significant benefits through waste reduction and enhanced efficiencies. By fostering collaboration, utilizing technology, and committing to continuous improvement, organizations can create a competitive advantage. Moreover, engaging staff in problem-solving initiatives fosters ownership and accountability across all levels. Lean supply chain management not only benefits cost reductions but also enhances overall customer satisfaction. As businesses continue to navigate complex market dynamics, infusing lean principles ensures that they remain agile and responsive. Embracing methodologies like Just-In-Time and Kaizen can further enhance operational effectiveness, enabling organizations to achieve their goals efficiently. Additionally, leveraging strategies such as Value Stream Mapping enhances visibility into supply chain processes, allowing businesses to remain proactive. Succeeding in today’s competitive landscape requires organizations to adopt a mindset of ongoing improvement and innovation. Therefore, those willing to embrace lean practices can achieve sustainable growth and operational excellence in the long run. Ultimately, by aligning their supply chain practices with lean principles, businesses can realize their full potential while minimizing costs.