Cost Analysis for Supply Chain Risk Management

In today’s fast-paced business environment, effective cost analysis is crucial for organizations aiming to manage risks within their supply chains. Understanding how various factors influence costs enables a company to identify potential risks early and take proactive measures. This involves examining the interplay between supply chain components and their direct impact on expenses. Companies should focus on key areas such as supplier reliability, transport efficiency, and inventory management. By developing comprehensive models that include fixed and variable costs associated with these components, organizations can better assess their exposure to risks. Identifying these areas will allow decision-makers to visualize where cost overruns are likely to occur. This allows for strategic adjustments that can be made to mitigate these risks. Leveraging data analytics and advanced forecasting techniques will enhance this analysis, ultimately leading to a more resilient supply chain. Additionally, regular training for employees about cost structures and potential risk factors can foster a risk-aware culture. Effective communication across departments is also vital to ensure everyone understands their role in maintaining supply chain integrity and minimizing costs. Continuous improvement targeted at these risk areas can result in significant savings and improved performance.

Identifying Key Cost Drivers

Identifying and analyzing key cost drivers is essential for effective supply chain risk management. Cost drivers are the factors that cause costs to increase or decrease, significantly impacting financial outcomes. Common cost drivers in supply chains include labor costs, raw material prices, inventory levels, and transportation expenses. By scrutinizing these elements, businesses can gain insights into where efficiencies can be realized or vulnerabilities addressed. Utilizing tools such as activity-based costing can provide clarity on how various activities relate to costs. This understanding enables companies to reorganize processes to eliminate waste and streamline operations. Furthermore, businesses should focus on benchmarking these drivers against best practices in the industry to identify areas needing attention. This approach also involves collaborating with suppliers to understand how fluctuations in the supply chain can affect cost structures. Implementing real-time tracking systems for inventory and transportation can further enhance the visibility of these cost drivers. Organizations that successfully monitor and analyze their cost drivers can apply strategic adjustments to minimize risks and allocate resources more effectively, ultimately leading to increased profitability and reduced exposure to unexpected expenses in the supply chain.

Assessing Risk Exposure

Assessing risk exposure is a critical aspect of effective cost analysis in supply chain management. Organizations must regularly evaluate potential risks and their impact on the cost structure. This involves identifying various risks, such as market volatility, supplier disruptions, and changes in regulatory requirements. Each of these risks carries a unique set of cost implications that can influence overall financial health. Implementing a risk assessment matrix can assist businesses in quantifying their risk exposure based on the probability and impact of various events. Each risk identified should be evaluated in the context of its potential financial repercussions on supply chains. Moreover, scenario analysis techniques can help simulate possible outcomes of identified risks, allowing decision-makers to prepare more effectively. Businesses should also engage in periodic reviews of their risk management strategies to adapt to changing circumstances. A proactive approach will aid in minimizing cost impact while ensuring continuity in supply chain operations. By routinely assessing and adjusting their risk profiles, organizations can promote resilience and guarantee that their supply chain remains robust in the face of potential threats.

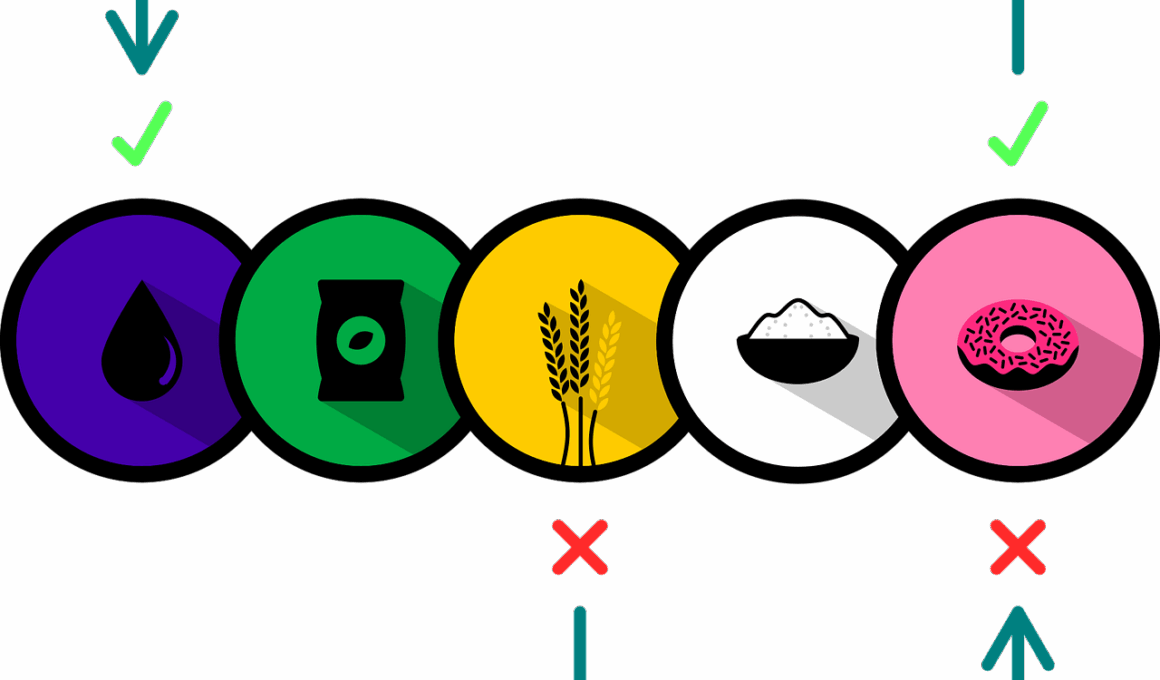

Mitigation Strategies

Mitigation strategies play a vital role in controlling costs associated with supply chain risks. By formulating effective strategies, organizations can respond promptly to identified vulnerabilities. Examples of such strategies include diversifying suppliers, incorporating alternative transportation methods, and investing in robust inventory management systems. Diversification of suppliers can reduce dependency on any single source, thereby minimizing the risk of interruptions in supply lines. Also, employing multiple transport logistics will ensure that businesses can react swiftly if one channel experiences disruption. Enhancing inventory systems with accurate forecasting tools can assist in maintaining optimal levels, thus reducing holding costs and risks of excess stock. Furthermore, organizations should consider implementing contractual agreements that delineate responsibility for unforeseen irregularities, thereby protecting against unexpected cost escalations. Training and empowering employees to identify and respond to potential risks quickly can build a resilient culture within the organization. All these strategies should align with the broader goals of the supply chain to ensure a cohesive and risk-aware working environment. Consistently reviewing and refining these mitigation strategies will aid businesses in adapting to evolving risks while controlling costs effectively.

The Role of Technology

Technological advancements significantly enhance cost management and risk reduction strategies within supply chain management. With the advent of big data analytics, organizations can analyze vast datasets to uncover trends and patterns related to cost and risk. These insights allow for more informed decision-making and more precise cost forecasts. Additionally, technologies such as Artificial Intelligence and Machine Learning provide predictive analytics to foresee potential disruptions and their cost implications. For instance, AI can enhance supply chain visibility by offering real-time monitoring and alerts for various metrics, enabling businesses to act preemptively. Furthermore, blockchain technology can improve transparency and traceability in the supply chain, minimizing risks related to fraud and errors. Implementing cloud-based solutions also facilitates better collaboration and information sharing among supply chain partners, ensuring that everyone is on the same page when it comes to risks and costs. Organizations investing in these technologies will not only improve operational efficiencies but also derive a competitive advantage. As technology continues to evolve, it is imperative for businesses to stay updated and embrace new tools that can help in managing costs and mitigating risks within their supply chains.

Regular Review and Adjustment

Regularly reviewing and adjusting risk management strategies is essential for sustaining effective cost analysis in supply chain management. The dynamic nature of global markets requires organizations to remain adaptable to various changes, such as new regulations or shifts in consumer demand. Establishing a systematic review process allows companies to assess their current risk management practices and evaluate their effectiveness. This might involve analyzing past incidents and their repercussions on costs, thus enabling organizations to learn from previous challenges. Additionally, engaging stakeholders from various departments can provide diverse perspectives on potential risks and cost factors, facilitating comprehensive analyses. Real-time feedback mechanisms can empower teams to make informed adjustments quickly based on evolving circumstances. Furthermore, businesses should implement key performance indicators (KPIs) to measure the effectiveness of risk mitigation strategies succinctly. By doing so, organizations can ensure that any necessary changes are made proactively rather than reactively. Maintaining a culture of continuous improvement encourages teams to seek innovative solutions while remaining vigilant about ongoing risks and their cost implications, ultimately supporting sustained growth and profitability in supply chain operations.

Conclusion

In conclusion, effective cost analysis for supply chain risk management is an ongoing process that necessitates continuous evaluation and adaptation. By identifying key cost drivers, assessing risk exposure, and implementing mitigation strategies, companies position themselves to navigate risks more effectively. Leveraging technology enhances the ability to monitor, analyze, and adjust supply chain operations, thereby reducing costs associated with disruptions. Additionally, fostering a culture of regular review and adjustment ensures that risk management strategies remain relevant and effective. As organizations thrive in uncertain environments, the ultimate goal is to maintain cost control while delivering high levels of service to customers. Efficiently managing these factors will establish a solid foundation for resilient supply chains capable of adapting to change. Thus, executives should prioritize investment in training, technology, and risk management tools to streamline operations. The collective impact of these actions will contribute significantly to safeguarding a firm’s bottom line while enhancing its competitive positioning. Focusing on these critical areas will ensure that businesses are not merely reactive but are proactive in managing costs and mitigating risks across their supply chains.