Capacity Utilization Metrics: How to Choose the Right One

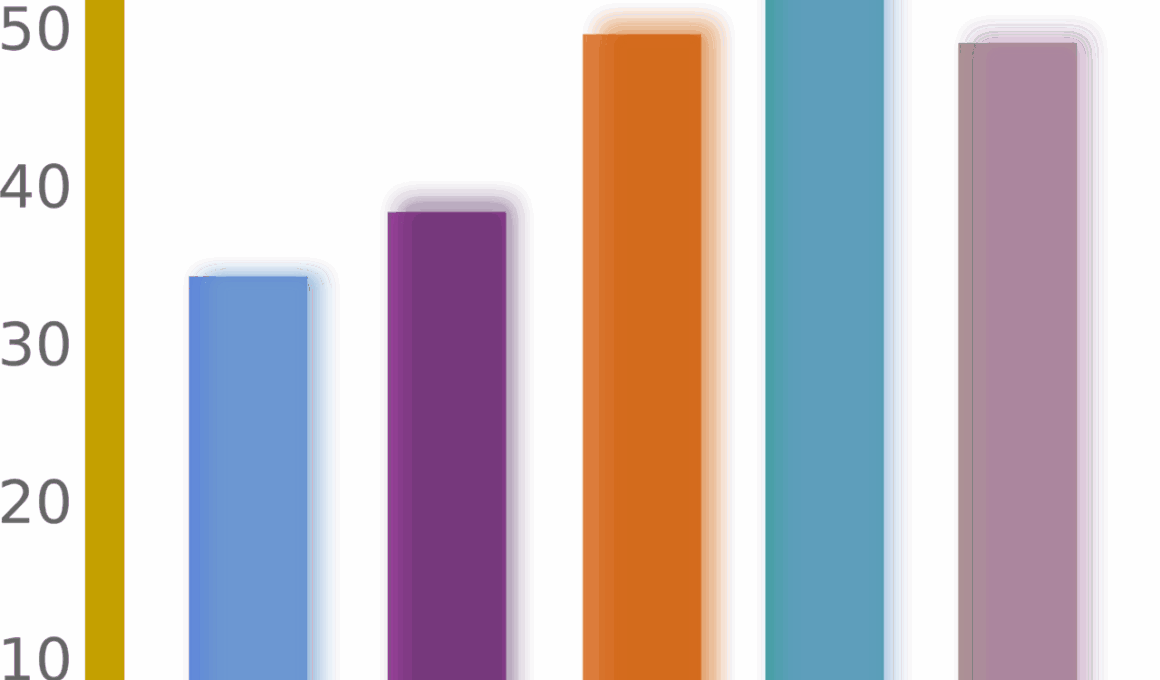

When evaluating economic health, capacity utilization is a key metric that reflects the extent to which a company or economy uses its production capacity. By measuring what portion of available production resources are utilized, businesses can identify gaps, inform strategic decisions, and optimize operational efficiency. Capacity utilization can reveal insights into demand, productivity levels, and potential areas for investment. A healthy capacity utilization rate often suggests robust economic conditions, while low rates may indicate underutilization, leading to higher costs per unit if not managed effectively. Therefore, understanding the right metrics is vital for comprehensive capacity assessment. By aligning capacity utilization measures with their specific organizational goals, companies can fine-tune production processes and respond effectively to market demands. Success hinges on choosing metrics that correlate with overall objectives while accounting for industry standards. Ultimately, by understanding how best to implement utilization metrics, organizations can drive efficiency and productivity, ensuring they remain competitive in dynamic markets. Comprehensive data analysis alongside utilization metrics can unveil opportunities for innovation and service improvement, setting a sound foundation for sustainable growth.

To effectively select the right capacity utilization metric, it’s essential to consider various factors that impact production processes and business goals. There are several methodologies available, each with its own advantages and drawbacks. Some common capacity utilization metrics include the overall equipment effectiveness (OEE), which measures the actual output divided by potential output. Other metrics focus on single units, labor productivity, or raw material efficiency, providing a multifaceted approach to understanding production capabilities. Regardless of the metric selected, organizations should aim to maintain a balance between efficiency and flexibility. High capacity utilization may indicate strong demand, yet it can also lead to increased wear on machinery and workforce burnout. Therefore, it’s important to ensure that chosen metrics align with the company’s long-term production strategy and adaptability to market changes. Additionally, maintaining open communication with teams can aid in understanding which metrics will yield the most actionable insights. By aligning team goals with strategic objectives through appropriate capacity utilization metrics, organizations can optimize production practices while remaining poised for growth in competitive industries.

Industry-Specific Considerations

Different industries face unique challenges that impact how capacity utilization metrics are applied and analyzed. In manufacturing, for instance, firms often prioritize equipment uptime, as delays can severely affect production schedules and profitability. Conversely, service industries may focus more on labor utilization and customer satisfaction rates, leveraging metrics that capture workforce efficiency. Selecting the right capacity utilization metric begins with understanding the industry context and specific operational challenges. For instance, in high-tech manufacturing, fluctuating technology demands may necessitate adaptive metrics that reflect seasonal changes in resource allocation. Consequently, companies should emphasize flexibility in their approach, refining metrics over time based on market conditions and operational feedback. Additionally, collaboration with sector-specific experts can illuminate which metrics yield valuable insights, guiding more informed decision-making processes. Each industry may also employ tailored benchmarks that indicate optimal capacity usage, allowing businesses to remain agile in the face of unexpected challenges, such as supply chain disruptions or economic downturns.

Incorporating technology into the analytics of capacity utilization can significantly enhance the decision-making process for businesses. Leveraging advanced data analytics, companies can derive deeper insights from utilization metrics. For example, utilizing machine learning algorithms can identify patterns that human analysts may overlook. Automation can streamline the data collection process, ensuring that companies have real-time insights into their capacity trends. Moreover, visualization tools can simplify the interpretation of complex data sets, making it easier for management to identify potential areas for improvement. With this approach, organizations can proactively address inefficiencies and explore alternative production strategies. By harnessing technological advances, businesses can create a more agile and adaptable production environment. Furthermore, capturing real-time data allows companies to dynamically adjust their operations based on changing market conditions, significantly increasing responsiveness. Investing in technology for capacity utilization analysis is not merely a trend but a necessity for maintaining competitive advantage in increasingly volatile economic landscapes. As businesses adopt these technologies, they position themselves to thrive in an ever-evolving marketplace.

Employee Engagement and Capacity Utilization

Employee engagement plays a critical role in optimizing capacity utilization metrics. Engaged employees tend to take greater ownership of their roles, often leading to innovations that improve efficiency and productivity. Companies that prioritize workforce engagement can create an environment where employees feel valued and empowered. This fosters collaboration, generating creative solutions to enhance output and minimize waste. Additionally, organizations should invest in training programs that educate employees about capacity utilization and its implications for their work. By aligning employee performance with capacity metrics, companies can rally their workforce around shared objectives. Implementing regular feedback mechanisms ensures employees are aware of their impact on production efficiency, encouraging a culture of continuous improvement. Recognizing achievements, no matter how small, can motivate teams to strive for higher utilization levels. Ultimately, when employees understand their roles within the broader context of capacity utilization, they become invaluable contributors to the company’s overall success. By cultivating this relationship, businesses can leverage the full potential of their workforce, harmonizing employee engagement with operational efficiency.

Monitoring capacity utilization metrics should be a continuous process, allowing businesses to adapt to market fluctuations and operational challenges. Regular assessments can help identify trends, enabling timely interventions that enhance efficiency levels. Companies can establish benchmarks by analyzing historical data, comparing these against current performance to identify any discrepancies. Setting realistic targets for capacity utilization provides a clear direction for operational teams, motivating staff to optimize processes. Furthermore, creating a culture of transparency around performance metrics encourages open dialogue between departments. This fosters collaboration, as teams work together toward achieving capacity goals while sharing best practices. It’s also essential to recognize seasonal variations in capacity usage; industries often experience periods of high demand followed by slower times. Understanding these cycles helps organizations plan maintenance schedules and workforce allocation effectively, maximizing productivity. Additionally, businesses should regularly revise their capacity utilization strategies to ensure alignment with changing business objectives and market realities. By staying proactive, organizations can ensure their resources are used effectively, maintaining an edge in a competitive landscape.

Conclusion: Towards Strategic Decisions

Ultimately, the choice of capacity utilization metrics can significantly impact a company’s performance and strategic decisions. A well-instituted capacity utilization framework allows organizations to identify growth opportunities, streamline operations, and adjust to emerging market trends. By keeping employees informed and engaged with their understanding of capacity metrics, businesses can enhance productivity. This, in turn, leads to better overall economic performance. The right metrics empower workers and management alike to make informed decisions that align production capabilities with market demands. Furthermore, leveraging technology and continuous monitoring enhances the accuracy and relevance of capacity utilization analytics. This approach fosters an environment of agility, allowing businesses to pivot when necessary. As a result, organizations become more resilient, ready to tackle challenges and seize opportunities as they arise. Therefore, companies should invest in understanding and refining their capacity utilization metrics, ensuring relevance and effectiveness in an ever-evolving economic landscape. In doing so, they lay the groundwork for sustained success and growth, driven by informed decision-making and a commitment to operational excellence.

.

By understanding the significance of capacity utilization metrics and choosing the appropriate ones for your organization, you actively contribute to your business’s success. Engaging employees, applying technology, and continuously evaluating performance contribute to optimized capacity utilization. This framework supports a comprehensive approach to resource management. It also promotes long-term growth and efficiency within the organization. Embracing this holistic understanding of capacity utilization paves the way for strategic alignment with broader business goals. Moreover, it cultivates a culture of collaboration and innovation across teams. The journey towards effective capacity management is ongoing, requiring adaptability and insight as market conditions evolve, embracing the future with confidence.