Cash Flow Implications of Supply Chain Disruptions in Inventory

Supply chain disruptions significantly affect cash flow management for businesses, particularly in the area of inventory control. These disruptions can arise from various sources, including natural disasters, geopolitical tensions, or global pandemics, which can lead to unexpected inventory shortages. As supply chains are often interdependent, a problem in one area can cause a ripple effect on others. Consequently, businesses may struggle to maintain adequate inventory levels, potentially leading to lost sales opportunities and diminished cash inflow. Companies must closely monitor their supply chains to identify potential vulnerabilities and mitigate risks proactively. Implementing tools such as demand forecasting and supplier diversification can help businesses maintain stability during disruptions.

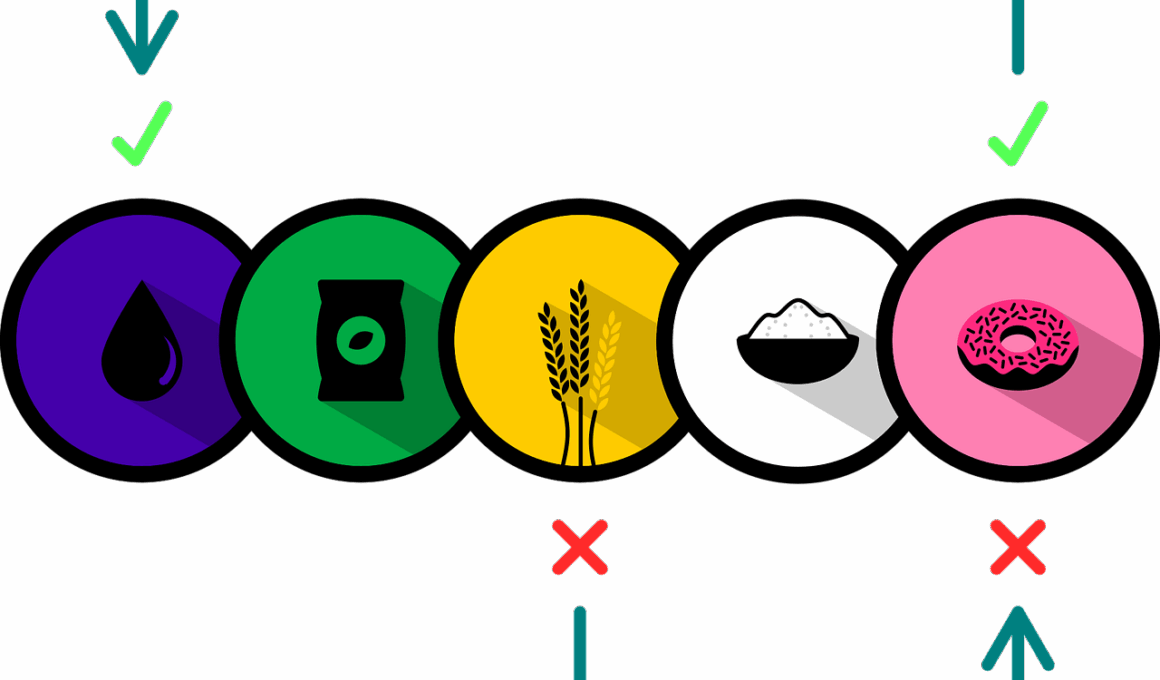

Bottlenecks in inventory replenishment primarily affect operational cash flow, as businesses may face increased costs or delays while waiting for essential products. Cash flow forecasting becomes increasingly complex under these conditions since the timing of revenue inflow is uncertain. Businesses may need to adapt their purchasing strategies to account for longer lead times or find alternative suppliers, which can incur additional costs. Organizations should also consider maintaining higher inventory levels as a precautionary measure, although this approach can tie up capital that could be used more efficiently elsewhere. Balancing stock levels against operational efficiency and cash flow requirements is crucial for sustaining profitability during uncertain times.

Effect on Profit Margins

Supply chain disruptions can lead to significant variations in procurement costs, thereby impacting profit margins for companies that rely heavily on timely deliveries. When delays occur, businesses may face increased shipping costs, fees for expedited services, or the need to source materials from less competitive suppliers. These unexpected expenses can erode profit margins, making cost management even more vital during these periods. Companies must analyze their supply chain to identify cost drivers and seek solutions that minimize the impact of disruptions on their bottom line. Implementing analytical tools or utilizing comprehensive supply chain management software can assist companies in developing cost-effective strategies.

Additionally, inventory turn rates may also decline due to supply chain disruptions, further exacerbating cash flow issues. When products are not readily available, it can slow down sales, leading to overstock of items that do not have strong demand. Businesses then must manage this excess inventory in a way that does not compromise cash flow. Organizations might consider strategies like discounting older stock or leveraging online sales avenues to accelerate turnover. Maintaining a proactive approach can help businesses navigate the complexities of disruptions and protect their cash flow. Remaining adaptable will ensure companies are better positioned for recovery when supply chains stabilize.

Customer Relationship Management

Customer trust often hinges on a company’s ability to deliver products consistently and on time. Disruptions can lead to longer lead times, which may disappoint customers and damage relationships. As a result, businesses may experience churn and declining customer loyalty, directly affecting revenue and cash flow. Companies should prioritize transparency in communication with their customers about any disruptions affecting their orders. Keeping customers informed can help manage expectations and maintain trust. Additionally, proactive engagement strategies—like offering substitutes or discounts—might retain customers during supply chain challenges, ensuring continued cash flow amidst difficulties.

Furthermore, businesses might consider reassessing their crisis management and response plans to account for future supply chain disruptions. Flexibility in operations is essential; forming close partnerships with multiple suppliers can provide options and greater resilience. Businesses can analyze how disasters affect their cash flow and develop alternative strategies that keep cash moving even when disruptions arise. Continuous improvement and crisis readiness enable companies to navigate uncertainties and minimize impacts on their cash flow. Regularly reviewing supply chain efficiency can ensure organizations are well-prepared for unexpected challenges ahead.

Conclusion and Strategic Recommendations

In conclusion, understanding the cash flow implications of supply chain disruptions is vital for business sustainability. It is crucial to maintain effective inventory and cash flow control, ensuring cash flow remains steady despite unforeseen disruptions. Strategic recommendations include diversifying supply sources, enhancing forecasting methods, and improving communication with customers. Businesses should invest in technology and analytics to monitor supply chain health in real-time, enabling faster response to any issues that may arise. Keeping the supply chain agile helps minimize cash flow impacts and preserves long-term profitability, making resilience a key component of strategic planning. Implementing the right strategies allows businesses to emerge stronger from future challenges.

Ultimately, continuous evaluation and adaptation become essential in a rapidly evolving market landscape where disruptions are common. Companies must remain vigilant and always ready to innovate, ensuring they can respond effectively to potential cash flow challenges. This involves not only investing in smarter supply chain management but also encouraging a culture of flexibility and resilience within organizations. By embracing these changes, businesses can significantly improve their chances of sustaining healthy cash flow during turbulent times in the market, positioning themselves favorably against competitors. A proactive approach to cash flow management, coupled with effective inventory control, ultimately leads to greater stability and success in the long run.