Cost Implications of Supply Chain Disruptions and How to Mitigate Them

Supply chain disruptions result in significant cost implications for businesses worldwide. These interruptions can stem from various sources such as natural disasters, political unrest, or global pandemics. The financial consequences include increased transportation costs, lost sales, and decreased productivity. Companies often need to respond swiftly to these disruptions to minimize their impacts. For instance, inventory shortages can lead to missed sales opportunities, impacting overall revenue. Additionally, the rising costs of raw materials due to scarcity can inflate product prices, ultimately affecting profit margins. Adopting effective mitigation strategies is crucial for long-term success. Improved forecasting and demand planning can help maintain optimal inventory levels. Collaborating with suppliers can also enhance overall supply chain resilience. Utilizing technology, such as data analytics and real-time tracking, can allow businesses to respond more swiftly to disruptions. Finally, establishing contingency plans ensures companies are prepared for unforeseen circumstances. These proactive measures can significantly decrease the adverse effects of supply chain disruptions, ultimately preserving customer satisfaction and maintaining overall financial health.

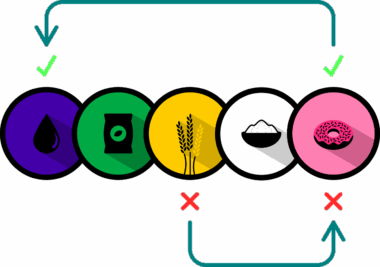

One critical aspect of mitigation strategies involves the assessment of risk within the supply chain. Understanding risks can help in prioritizing the areas that need immediate attention. Companies need to analyze potential vulnerabilities in their supply chains, considering factors like geographic risks or supplier reliability. Conducting a thorough risk assessment involves collaboration among various departments, including procurement and logistics. Regular reviews and updates to the risk management strategy ensure it remains relevant in a changing environment. Furthermore, diversifying suppliers can reduce dependency on a single source, thereby lowering risks. Companies should also invest in building stronger relationships with multiple suppliers to foster collaboration and flexibility. Supply chain resilience can be further enhanced by engaging in scenario planning, which allows businesses to simulate potential disruptions and test their responses. This proactive approach can lead to quicker, more efficient recovery during actual disruptions. Additionally, creating a culture of continuous improvement and learning within the organization can ensure that teams remain prepared for any challenge. Engaging in training exercises and simulations enhances readiness and can significantly mitigate overall supply chain disruption costs.

Implementing Technology in Supply Chain Management

Technology plays an essential role in modern supply chain management, especially during disruptions. Utilizing advanced analytics can provide insights into potential supply chain weaknesses, helping companies to preemptively address them. Moreover, adopting automation throughout the supply chain can enhance efficiency and reduce labor costs. For example, automated inventory systems can ensure that stock levels are adequately maintained, preventing shortages during high-demand periods. Implementing supply chain management software enables real-time visibility into processes, helping businesses respond quickly to disruptions. Mobile applications allow frontline staff to report issues immediately, increasing responsiveness. Additionally, these technologies facilitate better communication among stakeholders, ensuring everyone is informed during a crisis. Cloud-based solutions enable data sharing, offering a centralized platform for all involved parties. Furthermore, investing in artificial intelligence can help in predicting disruptions by analyzing patterns and trends. Predictive analytics can forecast potential supply chain shocks and suggest ways to mitigate them effectively. Integrating these technologies into everyday operations can create a more agile and responsive supply chain capable of navigating disruptions effectively. This tech-driven approach helps maintain competitiveness in today’s fast-paced business landscape.

Another key consideration in reducing supply chain costs is optimizing logistics operations. Efficient logistics management directly influences overall supply chain performance. Businesses must analyze their transportation networks to identify inefficiencies and areas to cut costs. For instance, consolidating shipments can reduce transportation expenses significantly. Logistics optimization can involve selecting the most cost-effective carriers while ensuring timely deliveries. Implementing route planning software can streamline transportation operations, enhancing overall efficiency. Regular communication with logistics partners can lead to improvements in service delivery and cost management. Moreover, embracing sustainable practices can also yield cost savings through reduced energy consumption and increased efficiency. Adopting technologies such as electric vehicles or optimizing warehouse layout reduces logistics costs while also promoting environmental sustainability. Moreover, leveraging third-party logistics (3PL) providers can allow companies to focus on core competencies while managing transportation and warehousing needs effectively. By outsourcing certain logistics functions, businesses can achieve significant cost reductions without sacrificing service quality. A well-optimized logistics operation ensures that products reach customers effectively and on time while keeping costs manageable and ensuring customer satisfaction.

Supplier Relationship Management for Cost Efficiency

Effective supplier relationship management is paramount for cost efficiency in the supply chain. Building strong partnerships with suppliers can create opportunities for collaboration and innovation. Regular communication with suppliers allows companies to stay informed about market movements, procurement trends, and potential risks. By fostering strategic partnerships, businesses can negotiate better prices and terms, ultimately leading to cost reductions. Additionally, establishing long-term contracts with reliable suppliers can mitigate supply chain disruptions and ensure stable pricing. Engaging suppliers in joint planning processes enhances transparency and trust, facilitating smoother operations. Collaboration can extend to sharing forecast data, allowing suppliers to prepare and align their production schedules accordingly. This proactive approach minimizes stockouts and ensures that businesses can meet demand consistently. Furthermore, supplier diversification can hedge against risks associated with relying on a single source. A varied supplier base increases competition, often leading to better pricing and service levels. Ultimately, investing in supplier relationships contributes to overall supply chain stability, enabling businesses to adapt to changes while keeping costs manageable and maintaining customer satisfaction.

Risk management and strategic sourcing are closely linked in supply chain cost reduction strategies. Developing a risk management framework allows organizations to identify and address potential threats proactively. This involves understanding both external and internal factors that could disrupt operations. By recognizing these risks, businesses can implement appropriate mitigation strategies. Strategic sourcing focuses on selecting suppliers who align with organizational goals while minimizing costs and risk. Using a thorough evaluation process, companies should assess supplier performance, quality, and reliability. Engaging in regular supplier audits ensures compliance and identifies areas for improvement. Diversifying supply sources, particularly in high-risk situations, can help manage supply chain uncertainties effectively. Additionally, leveraging technology in sourcing processes can enhance decision-making capabilities. Tools like e-sourcing and spend analysis can help organizations identify cost-saving opportunities within the procurement process. By streamlining sourcing activities and aligning them with risk management principles, companies can reduce operational costs while maintaining quality standards. Overall, an integrated approach to risk management and strategic sourcing supports a resilient and cost-effective supply chain in today’s volatile market.

The Role of Data Analytics in Supply Chain Cost Management

Data analytics plays a vital role in managing supply chain costs effectively. Organizations can leverage data to gain insights into their operations, identifying inefficient practices that lead to higher expenses. By analyzing historical data, companies can forecast demand more accurately, ensuring optimal inventory levels are maintained. Predictive analytics tools can help organizations anticipate market shifts and adjust their operations accordingly. Moreover, analyzing supplier performance data provides valuable insights into reliability and delivery times, allowing businesses to make informed decisions. Implementing dashboards that visualize key performance metrics can provide real-time insights into cost drivers. Cost-saving opportunities can arise by pinpointing areas where performance can be improved, such as reducing lead times or optimizing inventory turnover. Furthermore, utilizing big data can enhance supply chain decision-making by providing broader market insights. Data-driven decisions prevent businesses from relying solely on intuition, improving overall operational efficiency. Additionally, integrating data analytics into supply chain management can lead to better collaboration and communication with partners, promoting transparency and trust. Ultimately, a data-informed supply chain fosters cost reductions while enhancing customer satisfaction and operational resilience.

Finally, the implementation of continuous improvement practices can enhance supply chain cost management. Embracing a culture of continuous improvement encourages employees at all levels to identify inefficiencies and suggest solutions. Regularly reviewing processes and seeking employee feedback can uncover hidden cost drivers within the supply chain. Employing methodologies like Lean and Six Sigma can systematically eliminate waste and improve processes. Training employees in these methodologies creates a knowledgeable workforce committed to ongoing improvement. Implementing key performance indicators (KPIs) helps track progress toward cost reduction goals and ensures accountability within the organization. Additionally, investing in innovation can lead to significant efficiency improvements. Organizations should actively explore new technologies and improvements relevant to their supply chains. Conducting regular training and development sessions helps employees stay updated on best practices and innovations. Adopting a proactive approach enables organizations to adapt to changing market conditions and customer needs effectively. By fostering a culture focused on continual learning and enhancement, businesses can remain competitive while reducing operational costs. Sustaining a mindset of improvement promotes agility and resilience within the supply chain, ensuring long-term business success.